TOP > Report & Column > The Forefront of Space Science > 2015 > Forefront of the Materials Science and Engineering in Rocket Engine Development

![]()

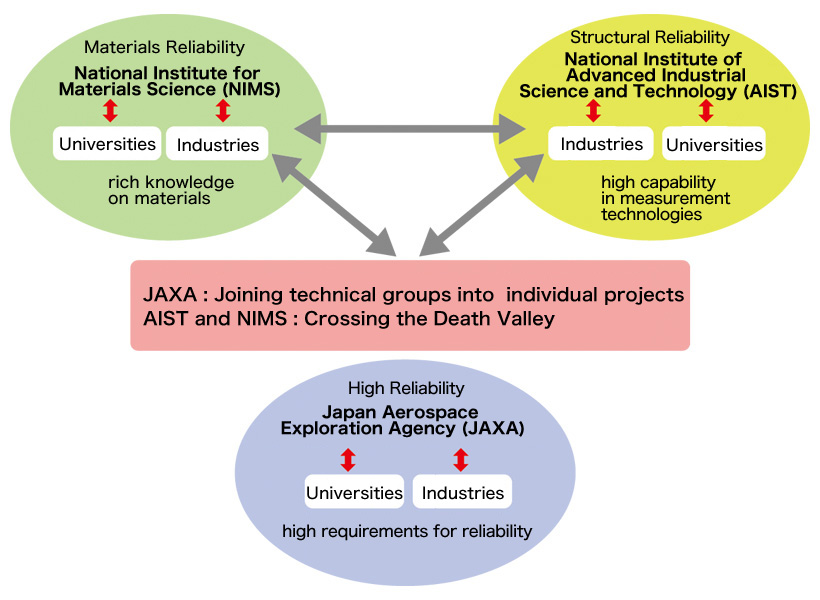

Materials Engineer = Merchant of Death? There is a Japanese saying that there are people who ride the mikoshi (the portable shrine), who carry the mikoshi, as well as those who make straw sandals (meaning that there are many people of different roles and occupations that make the society). One of the authors, as a materials engineer in ISAS, may be described as those who soften the straw behind the astronomers who conduct observations on the mikoshi (scientific satellites), the system engineers who carry the mikoshi and the structural engineers who make straw sandals (launch vehicles). The job of materials engineers is, originally, developing novel, light and strong materials. However, developing novel materials costs too much time to meet the schedule of space science projects. On the other hand, materials of the spacecraft are often used under extreme conditions; it makes it important to evaluate the features of the materials under the unique conditions of spacecrafts. Additionally, we are required to see whether those materials can stay robust without deteriorating under such harsh conditions through evaluating the reliability of the materials and structures nondestructively. Ironically, the history has been repeated that when space projects suffer big failures, attentions are paid on materials and quality assurance and budgets are made for the materials field so that researches and developments are accelerated, while there comes a cost reduction after many successes have been made. Formerly in the 1979E980, it was after the successive failures of the experimental geostationary communication satellite, Ayame 1 and 2, when radiographic testing technology for the propellants of the solid rocket motors (*1) was developed and the large X-ray computed tomography equipment was installed in the Tanegashima Space Center. And it was after the almost successive launch failures of H-II-5, -8, M-V-4, and H-IIA-6 during 1998E003, when deficiency in material data storage and nondestructive inspection were strongly pointed out. After the M-V-4 failure, the researches on the ultrasonic testing of graphite material were promoted to accomplish the official standards (JIS Z 2356 and ISO 10830) and the advanced array-type ultrasonic testing system. After the H-IIA-6 failure, we developed the ultrasonic testing equipment for thick components of composite materials. After the H-II-8 failure, which collected a large social attention, we have started to create the engine-related materials database with a cooperation of National Institute for Materials Science. As a party concerned, we are not intending to play the role of the merchants of death, but we would like to appeal strongly the importance of continuous researches and developments of basic material data storage and nondestructive inspection and evaluation. In that sense, the agreement on the collaborative research on nondestructive evaluation by National Institute of Materials (NIMS), National Institute of Advanced Industrial Science and Technology (AIST) and Japan Aerospace Exploration Agency (JAXA) is very meaningful for continuous researches and developments (Figure 1). With this agreement, in the JAXA projects join the technical groups in ALL-JAPAN beyond ALL-JAXA, and on the other hand NIMS and AIST are assisted to cross over the Death Valley between development and industrialization. In this paper, we are going to give brief introductions on the recent achievements on the material degradation, residual life assessment and nondestructive inspection of the combustion chamber wall of the liquid rocket engine conducted within the framework.

(*1) Solid rocket motor: Rockets are divided into solid-propellant rockets and liquid-fuel rockets. The kick motors of Ayame 1 and 2, the first stage motor of M-V-4 and the SRB-A of H-IIA-6 belong to the former while the second stage engine of H-II-5 and the first stage engine of H-II-8 belong to the later.

|

||||||