TOP > Report & Column > The Forefront of Space Science > 2005 > The Science of Containerless Levitation and Supercooled Melts

![]()

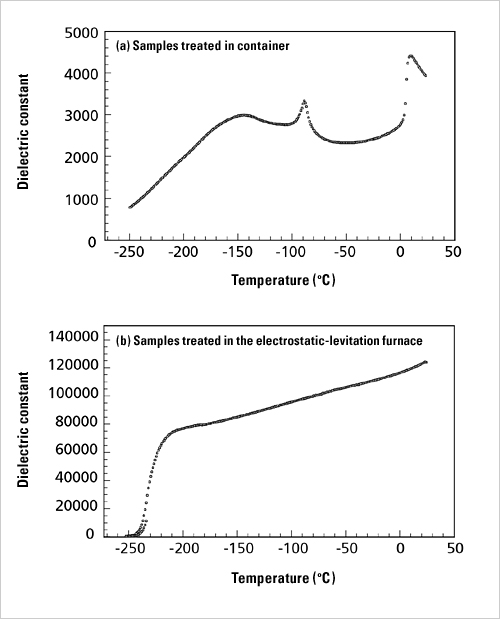

Creation of new functional materials using electrostatic levitation It is well known that steel is hardened by quenching, the rapid cooling from high-temperature. This is because rapid cooling forms crystals that differ from those of the normal coagulation state. Like this, the nature of materials can change greatly depending on the method of heat treatment. With containerless levitation, we can produce temperature conditions for an intensive supercooled state that cannot be obtained in a normal environment. By processing materials in these unique temperature conditions, we are trying to create unique crystal structures that show excellent new functions. In other words, we are creating new functional materials using the levitation method. Here is an example of our research in which a ceramics material was processed using an electrostatic-levitation furnace. The material is an oxide called barium titanate (BaTiO3), which is widely used in capacitors essential to electrical circuits. After the sample has been dissolved and solidified in the electrostatic- levitation furnace, we measured its dielectric constant. The result is shown in Fig. 4. The dielectric constant is an index to show the performance of capacitor materials. In normal state, barium titanate shows a high value of approx. 3,000. We found that barium titanate treated in the electrostatic-levitation furnace shows a value about 30 times higher than normal. Further, treated barium titanate has such an excellent temperature dependence that the high dielectric constant is maintained over wide temperature ranges.

Research on the creation of new functional materials using levitation technology has just started. We have strong expectations that excellent new materials like the above will be created in the future. Toward the Space Station Levitation technique is advancing well and various studies have been conducted on the ground. Research on the ground, however, indicates that a microgravity environment is required for certain experiments that are difficult to conduct on the ground. For example, samples that can be levitated on earth are limited to small ones, and some samples are very difficult to levitate against gravity. Furthermore, since gravity works on levitating samples on the ground, segmentation occurs with materials such as water-oil mixtures, and uniform mixing is therefore difficult. These difficulties can be overcome by experiments on the Space Station. It is essential that we proceed with our research by making effective use of both earth and space environments. An electrostatic-levitation furnace for the International Space Station is now being designed based on the research results on the ground. Though there are still many design hurdles to overcome, for example, the peculiar limitations of the Space Station such as equipment size and safety design to protect the life of the astronauts, we will continue the steady development of equipment for the Space Station. (Takehiko ISHIKAWA)

|

||||