TOP > Report & Column > The Forefront of Space Science > 2011 > Sand of Itokawa

![]()

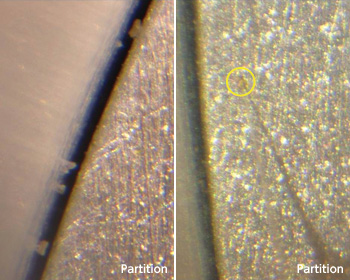

Keeping in mind the above points, we made the first attempt to recover the particles. We tried to pick up the particles attached to the wall of the sample catcher directly with an electrostatic-controlled micro-manipulator probe (Fig. 3). At left shows when we discovered several rocky particles, probably different from artificial material, inside the catcher. Due to static electricity, multiple relatively large particles were stuck to the space of the partition dividing rooms A and B. With this discovery, we became confident that many natural particles existed in the catcher, which relieved us and allowed us to investigate with confidence. It was more than two months after the return of HAYABUSA before we could confirm the existence of the natural rocky particles.

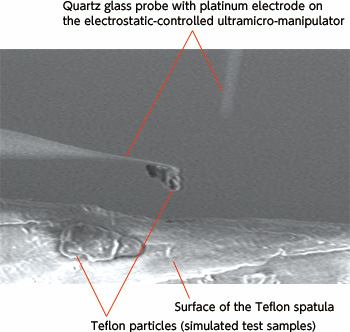

In the circle at the right of Fig. 3, a large particle can be seen as we were trying to pick it up with a voltage-applied probe. As you can see, poor visibility is a hindrance for the direct collection method. (The needle-like image is the probe's shadow: the actual probe can be seen faintly to the lower left of the shadow). The poor visibility was caused by: the relation of particle size to the catcher's surface roughness: limited direction of illumination in the depths of the catcher; and limited 3D information because of the unsecured microscope's view from two directions. To overcome the problem we devised some special techniques such as predicting height by measuring the shadow and detecting particles moving on the surface by scanning the high voltage-applied probe a little above the catcher's surface. These techniques were inefficient, however, so we adopted other recovery method. If large particles exist, then smaller ones exist in greater numbers. To recover the extremely fine particles, we used a Teflon spatula prepared in advance. Although its shape was suitable to sweep up the samples firmly stuck to the catcher's wall, we were unable to use it "as-is" because it blocked observation by the field emission scanning electron microscope (SEM). We fabricated several new spatulas, a SEM sample holder, and storage containers for the spatulas. We succeeded in picking up samples with the Teflon spatula, and, after SEM observation and analysis, we concluded that they originated from Itokawa*. Most of the extremely fine particles that adhered to the spatula were under 10µm in size and were difficult for us to identify with the optical microscope mounted in the clean chamber. We were unable to collect samples on the spatula when operating the manipulator viewed through the optical microscope. Later, we installed a newly developed ultramicro-manipulator inside the SEM to collect the extremely fine particles. Figure 4 shows when we were picking up test samples of particles with the ultramicro-manipulator in the SEM. With this method, we were able to recover even extremely fine particles swept up by the spatula, but particle collection inside the SEM took considerable time. This was because, while the manipulator moved in 3D inside the SEM, the SEM observation image was from a single direction only. We were forced to operate the ultramicro-manipulator very carefully.

Our current method is to overturn the sample catcher, shake it, gather the particles dropped from the catcher in the synthetic quartz glass lid, and then extract them from the lid with the micro-manipulator. Several hundred particles, including artificial ones, drop from rooms A and B with this method. It is easy to identify the particles on the flat quartz glass lid. Moreover, since we can operate the micro-manipulator while obtaining 3D information from the optical microscopes in two directions in good lighting conditions, we are able to recover the particles more safely and efficiently. When necessary, the static electricity can be neutralized by an ultraviolet lamp and/or Po-210 alpha-ray source. The latest collection and handling procedures are as follows: pick up particles from the quartz glass lid and transfer them to the SEM sample holder; examine the particles to remove the artificial ones; categorize the particles approximately; and move them with the micromanipulator to the synthetic quartz glass plate for storage. To protect the particles from pollution in the earth environment, all operations are performed in a clean chamber filled with highly purified nitrogen. The sample container used for moving the particles to and from the SEM is closed to the atmosphere and filled with highly purified nitrogen. SEM observation is performed in uncoated condition in order not to pollute the particles. In addition, observation and analysis are performed in a low-vacuum mode of highly purified nitrogen.

|

||||||||||