TOP > Report & Column > The Forefront of Space Science > 2007 > User-friendly Nontoxic Liquid Propulsion System with Future Potential ~ Paving the Way to a New Era of Space Transportation ~

![]()

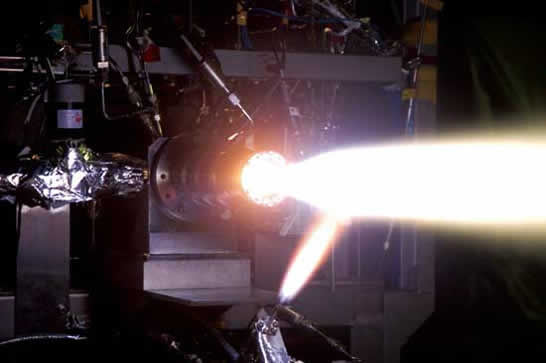

Experimental study of the propulsion system We have been studying the propulsion system since FY2003 under the theme “Study of N2O/ethanol Propulsion System,” part of the “Advanced Propulsion System Research” in the “Science and Engineering Experiments of Strategic Development and Research” of ISAS, JAXA. As the first step to acquire basic data for the design of a full-scale engine, we conducted two series of firing experiments (14 in total) in September 2004 and March 2006 using the experimental model with 700N-class thrust at the Noshiro Testing Center (NTC) as shown in Fig. 1 (*2). In these tests, we collected data to design the injector (the component that injects propellant into the combustion chamber), the most critical part in the engine, and the combustion chamber that is exposed to the most severe environment. At the same time, we organized issues associated with operations from propellant filling to actual combustion.

Since N2O’s vapor pressure at room temperature (20 deg. C) is approx. 5MPa, it can boil in the pipe from the tank to injector due to its pressure drop. In order to smoothly start combustion in our experimental model, we tried to cool the pipe using evaporative cooling by releasing a small amount of N2O before ignition. The density of N2O at room temperature is approx. 0.8g/cc but at freezing point it increased by 50% to approx. 1.2g/cc. Accordingly, as we try to reduce the tank volume by increasing density or lowering tank pressure in response to low pressure in the combustion chamber, it is convenient to handle N2O at a temperature between -90 to -80 deg. C. We checked the combustion performance and operability at this temperature. As a result of the two series of experiments conducted under a variety of firing conditions, we concluded that we could design the injector without use of any special heat-resistant materials and, further, it would be possible to adopt a combustion chamber made of light, heat-resistant composite materials. Thus, our experimental research progressed significantly toward the fabrication of a full-scale engine.

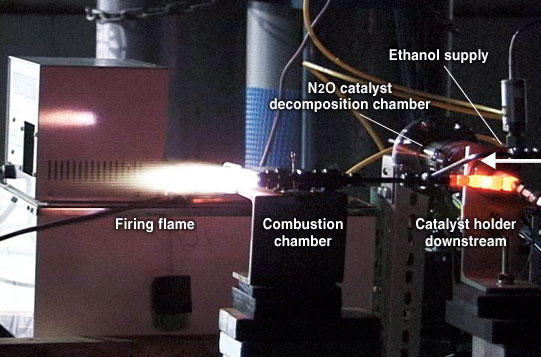

We are also proceeding with research on the igniter and attitude-control thruster using high-temperature gas generated in the decomposition of N2O. For more efficient decomposition, we are now testing the potential of a catalyst developed in another application that boasts almost 100% decomposition efficiency. As N2O is a very stable substance, it is difficult to decompose quickly. Nevertheless, we have obtained positive findings toward the actual application until now (Fig. 2).

|

||||||